Ts'ebetso ea tlhahiso ea likaroloana tsa polasetiki tse fetotsoeng haholo-holo e kenyelletsa: ts'ebetso ea ho kopanya, ts'ebetso ea extrusion, ho paka.

1. Liteko tse tšeletseng tsa ho kopanya: ho lefella, ho amohela, ho hloekisa, ho arola, ho sotha, ho kopanya.

2. Ho hloekisa mochine: e arotsoe ka lihlopha tse 'nè tsa A, B, C le D, tseo An e leng eona e phahameng ka ho fetisisa (e boreleli), joalo-joalo.

3. Kabelano ea lintho tse bonahalang: etsa bonnete ba hore lisebelisoa tse tala tse amehang li ke ke tsa fosa ts'ebetsong.

4. Ho kopanya: taelo ea ho kopanya ka kakaretso ke: phofo ea likaroloana, toner.

Ⅱ.Ho fepa.

Ka taolo ea k'homphieutha, ho koala ho laoloa ho latela ho fetoha ha boima ba 'mele.

Melemo:

1. Netefatsa ho nepahala ha tekanyo ea lintho tse bonahalang.

2. Fokotsa delamination ea thepa.

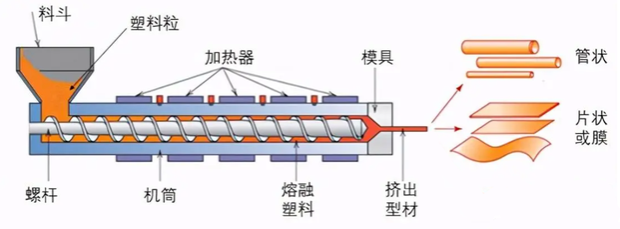

Ⅲ.Screw plasticizing, extrusion, ho taka.

Ⅲ.Screw plasticizing, extrusion, ho taka.

Ⅳ.Pholiso ea metsi (sink).

Folisa 'me u pholise lesela la polasetiki le ntšitsoeng ho tsoa ho extruder.

Ⅴ.Ho omisa moea (pompo ea metsi, thipa ea moea).

Tlosa mongobo ho tloha lesela la polasetiki ebe o o omisa.

Ⅵ.Granulation.

Ka kakaretso, boholo ba likaroloana tse sehiloeng ke 3mm * 3mm PVC standard standard: GB/T8815-2002.

Ⅶ.Ho thothomela (skrine se thothomelang).

Sefa likaroloana tse sehiloeng 'me u laole boholo ba likaroloana.

Ⅷ.Overmagnetization (sefahla sa makenete).

Monya likaroloana tse nang le litšila tsa tšepe.

Ⅸ.Ho hlahloba setšeng.

Haholo-holo ke taolo ea ponahalo, e bonang hore na 'mala oa likaroloana o fihla ho maemo le hore na o kopane.

Ⅹ.Ho kopanya (motsoako oa rotary oa cone habeli).

Netefatsa hore 'mala le ts'ebetso ea likaroloana tsa polasetiki tse fetotsoeng li tšoana.

Ⅺ.Packaging (mochini oa ho paka oa elektronike kaofela).

Ⅻ.Polokelo

Nako ea poso: 23-12-22