(1) tšusumetso ea lisebelisoa tse tala

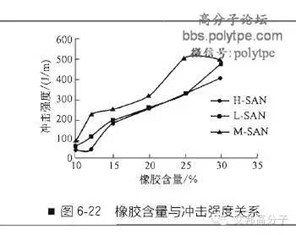

Lihlahisoa tse fapaneng tsa PC le ABS Resun Cland ea Alloy e na le phapang e kholo ts'ebetsong. E ka bonoa ho setšoantšo sa 6-22 hore dikahare tse phahameng tsa rabara li ntlafatsa matla a tšusumetso lipakeng tsa li-alloy, ka hona li fokotsa maemo a anyesang anyeti. Ka hona, khetha ab ka direche tse loketseng tsa lithibelo li ke ke tsa ntlafatsa matla a ho susumetsa feela, empa li ntlafatsa matla a tsona a ho ikhula ka lehare. Ha ABE e nang le litaba tse tlase tse tlase li sebelisoa, matla a anyesang a anye le a anyang a tla bonahala eka a ntlafatsoa. Ntle le moo, litaba tse ngata tsa merara e phahameng le boima ba molek'hule e ka ntlafatsang mocheso mocheso oa alloy.

(2) Tšusumetso ea karolo ea PC / ABS e kopanngoang palo ea alloy

Ho tsamaisana le thepa ea ho kopanya pc / af e amana ka kotloloho le litaba tsa karolo e 'ngoe le e' ngoe tsamaisong. Cao Mingan et al. Ba fumane PC / ABB e se nang litšobotsi tse fapaneng ka ho fetola karohano e kopanyang PC le ABS Rentin. Thepa ea PC / AFY Alloy e na le kamano ea mela le litaba tsa AB, 'me tse ngata li boloka lekhoba la joala. Meruti ea Kakaretso ea PC / ABY Alloy e pakeng tsa PC le ABS, 'me matla a tšusumetso a na le phello ea superatradtivity (ke hore Synenegy e be le phello) le pherekano ea tumelo.

(3) phello ea karolo ea boraro

Ho hanyetsa mocheso le ho tsitsipana ha mocheso ho ka ntlafatsoa ka ho eketsa Benzothiazole le polymide. Ho pharalla ha PC / ABYFY ho ka ntlafatsoa ka ho eketsa mesifa ea ethylene oxide block copolymer le a acrygeste. Ntle le moo, e le hore u ntlafatse lihlahisoa tse kopaneng tsa lihlahisoa tsa PC / ACYER SAN, SBROER kapa graft copole le lintho tse ling hangata li eketsoa.

(4) Tšusumetso ea Theknoloji ea ho sebetsa

PC le lisebelisoa tse bulang ka bongata li ka khetha ho tloha bo-screw sextruder le sethala se le seng sextruder se nang le motsoako oa static. Jong Han Chun o lumela hore phello ea ho se lumellane le Nako e telele e loketse. Mabapi le mokhoa o kopanyang, phello ea ho kopanya la bobeli ho feta. Leha ho le joalo, karolong ea bobeli ea taelo e hloka ho phethoa habeli ka mocheso o phahameng, e nang le tšebeliso e phahameng, e bonolo ho nyenyefatsa thepa le ho fokotsa thepa ea alloy.

Mokhoa oa boqapi o boetse o na le tšusumetso e kholo ho morphology le sebopeho sa PC / ALGY. Mohlala, mofuta o thehiloeng ka ho tobetsa polasetiki o matlafatsang o ka fokolisang komporo ea limela, ha o ntse o bopa, o fetoha le ho feta. Ka hona, matla a maikutlo a semelo a mabeli a na le phapang e kholo, 'me matla matla a khatello ea khatello ea khatello ea maikutlo a phahame. PC ka metsing (Litaba tsa metsi li kholo ho feta 0.03%) le mocheso o phahameng (mocheso o lokela ho qoba li-ecid tse ntle, e le hore li se ke tsa ama ts'ebetso ea lihlahisoa.

Nako ea poso: 02-06-22