Biodegradable Filimi e fetotsoeng ea Video-Spla

Ts'ebeliso ea li-polylactic acid joale li feta ntle le moriana linthong tse tloaelehileng tse kang mekotla ea lijarete, lifilimi tse nang le likhoele, mamati le likopi. Moo thepa e entsoeng ka polylactic amid o ne a le theko e boima, empa joale e se e se e le e 'ngoe ea thepa e atileng haholo ea ho kenya liphutheloana. Poly (lactic acid) e ka etsoa ka likhoele le lifilimi ka ho qeta khato, ente ho hlapaola le ho otlolla. Ho nepahala ha moea le ho nepahala ha filimi ea acid acid ho feta ea filystyrene. Kaha limolek'hule tsa metsi le khase li fapane haufi le sebaka sa mohohlobi, metsi le moea o ho loketseng ka ho fetola kristactic acid.

Mahlale a mangata a kang a tsamaisa, a etsa litšupiso tse nang le likhoele kapa likaroloana, ke likheo tsa ho kenyelletsa mekhabiso ea litsuopo. Polylactic acid e ka sebetsoa joalo ka li-armoplastics tse ngata fiber (mohlala, ho sebelisa lits'ebetso tse matlafatsang) le filimi. Pla o na le thepa e tšoanang ea mecha ea ho pete polymer, empa e na le mocheso o tsoelang pele o tsoelang pele. Ka matla a maholo, phele e na le khatiso e bonolo e e sebelisoang haholo ho 3-D. Matla a hlasimolohileng a plation ea 3-D e hatisitsoeng pele e ne e ikemiselitse.

Litšobotsi tsa SSLA

Tlhaloso ea lithoto tsa Biodegradadadadadadadadadadadadadadadadad ho Carbon Dioxide (Co2) le / kapa methane (Ch4), metsi (le micharase e ncha (joalo ka mmele o mocha (joalo-joalo) oa polasetiki ea kokoana-hloko.

Spla Main Action Action

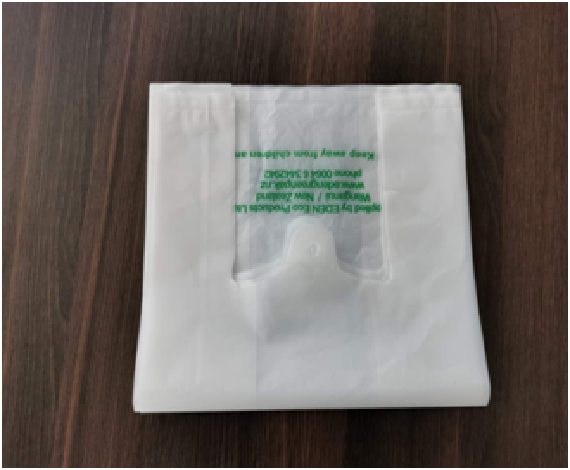

E ka khutlisa mekotla ea pakete ea polasetiki ka botlalo, joalo ka mekotla ea mabenkele, mekotla ea mabenkele, fana ka mekotla, mekotla ea lithōle, mekotla ea khase, bokhalase

Sptse grade le tlhaloso

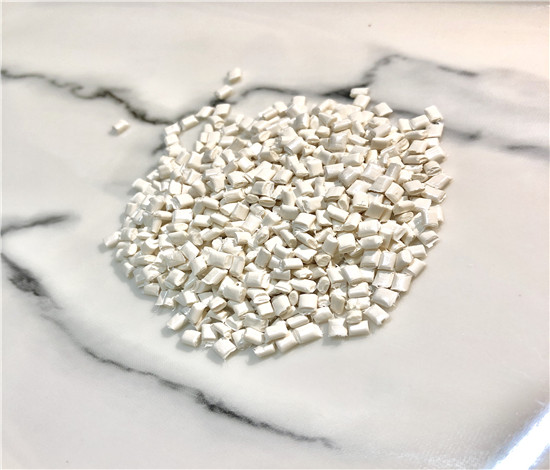

| Keletso | Tlhaloso | Ho sebetsa Litaelo |

| Spla-F111 | Lintlha tsa mantlha tsa lihlahisoa tsa Spla-F111 ke pla le ho li-PBA, 'me qetellong li entsoe ka li-carbon dioxide le metsi, ntle le ho silafatsa tikoloho. | Ha o sebelisa filimi ea Spla-F111 hodima moleng oa tlhahiso ea lifilimi, o khothalelitsoe o phatlohang oa lipalesa tsa filimi ea lifilimi ke 140-160 ℃. |

| Spla-F112 | Lihlahisoa tsa mantlha tsa Lihlahisoa tsa SGLA-F112 ke PLA, PBAT le starch, le lihlahisoa tsa eona li ka hlahisa carbon dioxide le metsi ntle le ho silafatsa tikoloho. | Ha o sebelisa filimi ea Spla-F112 ka mohala oa tlhahiso ea lifilimi, e khothalelitsoeng folete ea filimi ea phepelo ea lifilimi ke 140-160 ℃. |

| Spla-F113 | Likarolo tsa mantlha tsa lihlahisoa tsa SPLA-F113 ke pla, PBAT le lintho tse sa tloaelehang. Lihlahisoa li ka ba 100% tse entsoeng ka mor'a ho sebelisa 'me u lahliloe' me qetellong li hlahisa khabone le metsi ntle le ho silafatsa tikoloho. | Ha o sebelisa filimi ea Spla-F113 ho mohala oa tlhahiso ea lifilimi, o khothalelitsoeng o phatlohang oa lipalesa tsa lifilimi ke 140-165 ℃. |

| Spla-F114 | Sehlahisoa sa Spla-F114 ke sethala sa polyethylene se fetotsoeng. E sebelisa starch ea 50% e tsoetseng pele hodima polyethylene ho tsoa lisebelisoa tsa peterochemical. | Sehlahisoa se kopantsoe le polyethylene ho mola oa tlhahiso ea lifilimi. Chelete e khothalelitsoeng ke 20-60 ea%, le mocheso oa filimi oa bongaka ke 135-160 ℃. |